“The NTUiTiV Difference” – This is Why This Course is Right for You

- Special Discounted Price of US$3,950 – the usual price is US$4,950

- Satisfaction Guaranteed – or we will give you your money back!

- 15% Early-bird Discount – for the first 3 people to register for any course

- 20% Group Discount – if you come with one or more colleagues

- No More Than 12 Delegates on the course – guaranteed

See our homepage for more detailed information about these NTUiTiV Differences.

Jumpstart process excellence—typical skills for real-world improvement projects.

This dynamic 5-day programme introduces professionals to Lean Six Sigma principles, tools, and applications across DMAIC. Participants will build practical skills in process mapping, data analysis, and performance measurement, supported by hands-on exercises and real-life case challenges designed to deliver tangible efficiency gains.

Why this course is important

-

Real impact from day one – Small but structured improvements in processes can yield measurable cost savings and quality improvements.

-

Bridging theory and practice – Understanding data-driven decision-making positions delegates to be credible process owners and change champions.

-

Foundation for future growth – Completing this course enables delegates to support or lead larger Lean Six Sigma projects, preparing them for Green Belt progression.

Who should attend

-

Operations supervisors, production managers, and process coordinators seeking to improve service or manufacturing performance

-

Quality, continuous improvement, and operational excellence professionals initiating problem-solving projects

-

Team leaders and analysts from finance, logistics, healthcare, retail, and telecom sectors

-

Professionals aiming to embed structured process-improvement methodologies across departments

What you will learn

-

Lean Six Sigma fundamentals – Understand the DMAIC structure and the role of Yellow Belts in improvement initiatives

-

Process mapping & SIPOC – Visualise workflows, identify value streams, and scope high-impact projects

-

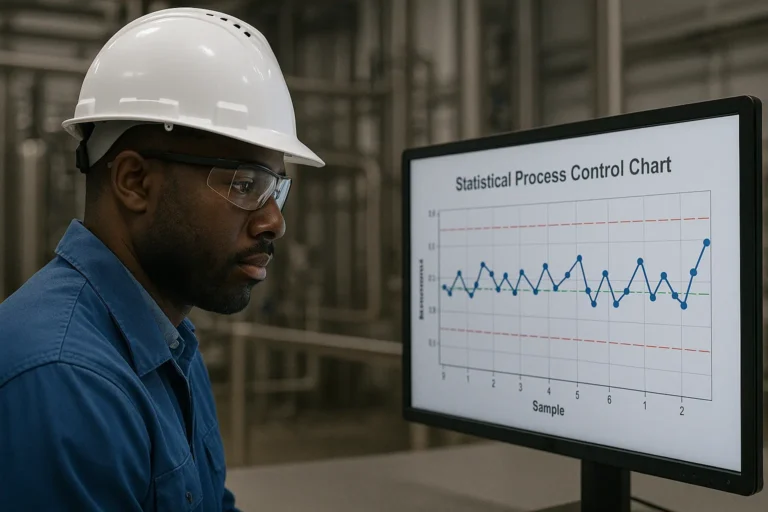

Basic statistical tools – Use run charts, Pareto analysis, and measures of central tendency for performance insights

-

Root cause analysis – Apply 5 Whys, Fishbone diagrams, and cause-effect techniques to pinpoint issues

-

Control tools & metrics – Establish key performance indicators and basic control strategies to sustain gains

-

Change management & communication – Engage stakeholders, manage resistance, and sustain engagement

-

Project simulation – Work on real-world scenarios to apply tools, present findings, and propose improvements